Gunze: Tech-Savvy Innerwear Steeped in Japanese Tradition

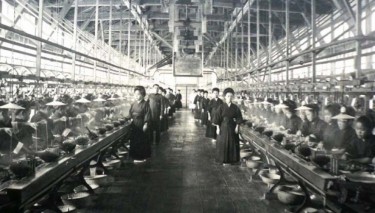

A lover of fine cloth, silk was highly prized by the reigning family and Kyoto became a mecca for luxury fabrics; pushed on by textile merchants like Gunze.

Japan is home to many traditionally-made cottons, crafted from a lineage that stems back to the time of Emperors. But the ancient technique of Japanese fabrication is slowing down from generation to generation, with only a few mills upholding their regional textile customs today. Based in the city of Nishiwaki in Japan’s Hyogo Prefecture, Maruman is a manufacturer specializing in yarn-dyed cotton fabric or Banshu Ori.

With a history of over two centuries, Maruman opened its doors in 1901. The founding Maruyama family was of a merchant bloodline and were in close contact with bankers in Nishiwaki. This alllowed the family to tap investment for textile production without much opposition.

The Maruyama family went on to acquire 400 jacquard weaving machines and began selling textiles in Osaka. But after the destruction of the Second World War in Japan, the mill was forced to close. Reopening years later as Maruman, the mill commenced as an agent for a major cotton-spinning company, before once again stepping back into textile production.

As a region, Nishiwaki textile mills developed immensely in the Seventies and Eighties, exporting huge amounts to overseas clients in Europe and North America. Maruman remains one of the key mills in this region today, creating original, made-to-order fabrics for clients seeking quality shirting and blouse materials.

Maruman’s forte is the texture-quality of its fabrics. All cotton yarns are sourced from Egypt, Peru, China and India, which are then spun in India, Indonesia, China, Switzerland and Italy, as well as more locally, in Japan.

Having received the purchased yarn, the Maruman magic happens. The mill is one of just several remaining practitioners of ‘Banshu Ori’; the making of cotton textiles by dyeing, weaving and finishing in one continuous production cycle.

“Banshu Ori is an intra-industry specialization that enables us to choose how we weave and finish our fabrics,” explains Tsuneo Maruyama, president of Maruman.

“And every factory has their own characteristics, which is expressed in the fabrics.”

Maruman yarns are dyed in advance and patterns are woven using the dyed yarns, giving off a natural texture, good tint and an abundance of color once finished.

According to Maruyama, Banshu is a solid manufacturing technique for upholding textile quality – from dye to finish.

“It’s a smooth way to produce textiles of high stability, especially thin textiles made of cotton. And it’s great for dress shirts.”

Although Maruman works mainly with cotton, it still develops textiles using paper, cupra tencel, and linen. And one of their best-selling fabric types is jacquard. They offer an array of compact cotton fabrics for shirting and thinner cotton-tencel fabrics for women’s blouses. And because of their custom ordering scheme, designers feel at home working with them.

“Because we have a flexible mind, we can create a variety of textiles,” explains Maruyama, who lists fashion designer-turned–interior designer Jhane Barnes as a top Maruman client – since the Eighties.

“We have both dobby and jacquard systems on site, and our technical design team are experts who like trying out new things with new materials.”

Maruman designs and produces new fabrics to correlate with fashion’s seasonal calendar. Having developed a system that integrates trends with evergreen pieces, the firm has over 50,000 textile samples in their warehouse to date, all ready to be tweaked by clients or bought as they are.

Maruman’s newest material is one of a different kind, the Oji fiber, made from paper.

“We’ve found a golden composition using cotton as the warp and paper yarn as a part of the weft,” says Maruyama. “The fabric, with the paper yarn, is amazingly light with a nice texture on the skin, which is ideal for summer.

Sourced from paper maker, Ojo, the concept of the paper yarn stems back to the days when producers would make paper from mitsumata, kouzo or linen. Then, they’d slice it into thin tape, before finally twisting it into yarn. The Oji is Maruman’s push into eco-textiles, are clothing made from this fiber breaks down into carbon dioxide and water in the soil when discarded.

The authentic structure of the paper yarn mixed with the tradition of Banshu, looks to be longstanding, special type of partnership for Maruman, adds Maruyama, who believes the material sets them apart in the region.

“So far, we are the only producer of both this type of yarn-dyed and piece-dyed paper woven in Japan.”

The latest collection from Maruman is available for purchase online with Le Souk.

The article was written by Benjamim Fitzgerald, and appears courtesy of Le Souk.

Website: www.lesouk.co