Commentary & Critique - Angora; An Argument for the Ethical Treatment of Animals

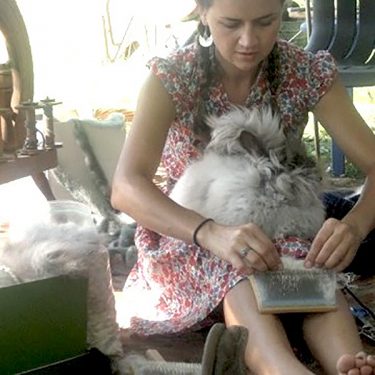

The debate on the ethics and animal welfare of angora rabbits, and the resulting clothing made from it, has been raging in the media for sometime now.

The idiom “One man’s trash is another man’s treasure” couldn’t be more true than in upcycling, which embodies the concept that what one person considers worthless, another considers valuable. Many genres of artistic expression have long found value in what society discards. Artists, and as an extension, designers, are particularly gifted in finding value in what others devalue. In the case of pre consumer waste, the concept of repurposing trash is simply interpreted at an industrial level, through the waste created during production.

Manufacturers and designers in the mainstream fashion industry discard on average 15% of materials en route to production. That is 15% of waste at every stage of production, from fiber to finished garment, waste that is more often than not, simply discarded and sent to landfill or incinerated. Wasted fiber right from source, cotton left unpicked, sheep fleece burned due to poor market prices, mistakes and errors at the weaving and knitting stage, damaged dye lots, discarded lab dips, print tests and swatches, textile overages, production left overs, and damaged finished garments, all constitute pre consumer waste.

The reuse of these otherwise valueless materials is considered upcyling, as opposed to recycling or downcycling. Recycling by its nature is simply a reuse, or repurposing of materials, and generally used as a catch-all phrase that encompasses upcycling and downcycling. Downcycling is the reuse of materials in such a way that the end use is less valuable than the original use, for example, damaged textiles being used for car seat stuffing. Upcycling is the reuse of materials through creative expression and labour that results in the end product being valued more highly than the materials used to create it. Using a textile mills sample swatches, or an apparel manufacturers production cutting waste to fashion finished garments, is therefore considered upcycling.

The reuse of these otherwise valueless materials is considered upcyling, as opposed to recycling or downcycling. Recycling by its nature is simply a reuse, or repurposing of materials, and generally used as a catch-all phrase that encompasses upcycling and downcycling. Downcycling is the reuse of materials in such a way that the end use is less valuable than the original use, for example, damaged textiles being used for car seat stuffing. Upcycling is the reuse of materials through creative expression and labour that results in the end product being valued more highly than the materials used to create it. Using a textile mills sample swatches, or an apparel manufacturers production cutting waste to fashion finished garments, is therefore considered upcycling.

Many designers have come to see industrial textile waste as a resource instead of valueless excess. One of the most noted of the designers working with pre consumer waste, is perhaps Orsola de Castro’s From Somewhere, based in London. According to de Castro, “in an industry which, is increasingly overproducing, very little is being done to highlight how much is discarded at source, and yet what is being thrown away is often intact, still beautiful, and still useable if thought of in a different way.” Working with some of the finest manufacturers in Italy, De Castro reimagines and refashions cutting-room scraps and manufacturers’ headers into fun, playful, well-designed dresses and separates. Each piece is individually cut, with an eclectic and original use of colour and paneling, making From Somewhere pieces instantly recognizable, despite the eclectic and varied nature of the materials. The beauty of each piece is in its uncompromising balance between contemporary design and a poetic and ethical solution to waste.

Talking with a wide range of designers working with discarded materials, they all agree that one of the greatest challenges is the diverse nature of the materials themselves, with variations in color, texture, weight and size. For brands wholesaling their collection, that also requires re-educating retail buyers to understand the variability in materials and colors, rather than the specificity they are used to. The individuality of the source material, also makes it difficult to scale production, as each swatch has to be thoughtfully selected and coordinated to create a balanced whole. According to Elizabeth Brunner of US based Piece x Piece, “The manufacturing and sourcing process is extremely involved and time consuming, with each scrap of fabric carefully chosen and coordinated with others, and pieced and placed to form a garment.” Scaling production is an ongoing issue for designers working with pre-and-post consumer waste, as with scale comes profit. Never the less the increased labor costs are balanced to some degree by the reduced material costs, with most materials donated free of charge. According to de Castro, “We used to have to really convince the manufacturers to give us their leftovers, but now we are approached by companies wanting to achieve creative waste management as part of their greenification.” The factory de Castro works with “recycle for us rather the way you would at home, so when I arrive there, there are these bags already prepared for From Somewhere… so they already have a system.“ Austrian label Steinwidder works with repurposing a rather more unique source of pre consumer waste, to produce an authentic, unique and creative women’s wear collection. The collection is produced from damaged pre-consumer factory made socks. Working directly with a sock manufacturer, the socks are reconfigured by Steinwidder into an edgy, urbane women’s wear collection, with the monochromatic designs capitalizing on the textural and scale variations in the source material. Anita Steinwidder explains her process; “The socks are interlocked together, like an oversized jigsaw puzzle, to make a continuous piece of fabric, then styled into individual designs.” Highlighting that the creative use of otherwise wasted materials is only limited by imagination, creativity and labor.

Through their collaboration with Speedo, From Somewhere have managed to scale up production from single unique items to limited production runs, through the donation of unused ‘dead stock’ materials from Speedo’s banned LZR racer suit. All manufacturers end up accumulating ‘dead stock’ fabric; left overs, canceled orders, textiles bought or dyed in colors no longer desirable, or in Speedo’s case, materials banned from their intended use. Branded and exclusive textiles are often incinerated, while others are sold to a middleman or ‘jobber’ for very little money, as a means of generating cash flow, and liberating storage space. These material overages are often bought by emerging designers, as a means of avoiding order minimums, posing the question; why not cut the middle man out, and build direct relationships such as the one Orsola de Castro enjoys with her Italian manufacturers? Other designers have achieved success with this strategy, such as London Fashion Week New Gen Designer of the Year, Christopher Raeburn, who specializes in sourcing military and direct from mill, dead stock fabric.

Another means of scaling production has been achieved by Danish brand R.ds, who recut swatches to a standard size to make piecing more regulated. They also narrow the range of fabrications sourced to minimize the amount of individual matching and piecing required. R.ds who work with some of the premier Italian men’s wear manufacturers, produce simple unconstructed pieces that “don’t require a designer to mix and match, (but instead) leave the process entrusted entirely to their seamstresses.” In the case of major high street brands, there lies the opportunity to cannibalize and reuse their own waste at source, and at a very large scale, due to their production capabilities. Simply put, making more garments, means producing more waste, which could result in larger scale upcycling projects. Some inroads have been made, such as with Orsola de Castro and Tesco’s F&F line, where the designer was invited by the retailer to design a capsule collection utilizing their left over jersey fabric from the previous season. De Castro is also working with high street giant Top Shop in a similar effort to reuse their left over materials, obsolete textiles, unfinished stock, and damaged fabric. Preliminary figures are impressive, with the first collection selling out in 3 days, and a second season planned, doubling production.

This is a major area of potential future capitalization, with large-scale manufacturers repurposing their own waste, through designer collaborations, to redesign and reimagine their leftover textiles. Imagine H&M partnering with an established eco designer to design an exclusive collection from their leftover fabrics, or challenging a luxury designer to design with their offcuts, promoted and sold with all the hype that exists around their current ‘limited edition’ designer collaborations. De Castro believes, that“ if big manufacturers had an in-house ‘recyclist’, trained to analyze waste before it became rubbish, and factories made way for an upcycling line (just as most now have a sampling unit and internal design studio)”, this would solve the problem of producing upcycled designs en mass. As Orsola de Castro says “The difficulties we are encountering in upscaling this system aren’t due to unfeasibility, but to the inevitable slowing down that upcycling requires, making third party manufacturers reluctant to embrace the method.”

This is a major area of potential future capitalization, with large-scale manufacturers repurposing their own waste, through designer collaborations, to redesign and reimagine their leftover textiles. Imagine H&M partnering with an established eco designer to design an exclusive collection from their leftover fabrics, or challenging a luxury designer to design with their offcuts, promoted and sold with all the hype that exists around their current ‘limited edition’ designer collaborations. De Castro believes, that“ if big manufacturers had an in-house ‘recyclist’, trained to analyze waste before it became rubbish, and factories made way for an upcycling line (just as most now have a sampling unit and internal design studio)”, this would solve the problem of producing upcycled designs en mass. As Orsola de Castro says “The difficulties we are encountering in upscaling this system aren’t due to unfeasibility, but to the inevitable slowing down that upcycling requires, making third party manufacturers reluctant to embrace the method.”

There seems to be a complete dearth of designers in Sweden working with pre consumer waste, making this an opportunity for small, artisanal designers to access unique materials at low or no cost, small scale manufacturers to find ethical means of eliminating their waste through donations direct to designers, and large scale manufacturers to utilize their waste at source through designer collaborations.

Website: www.textiletoolbox.com